Are SMT and SMD the same?

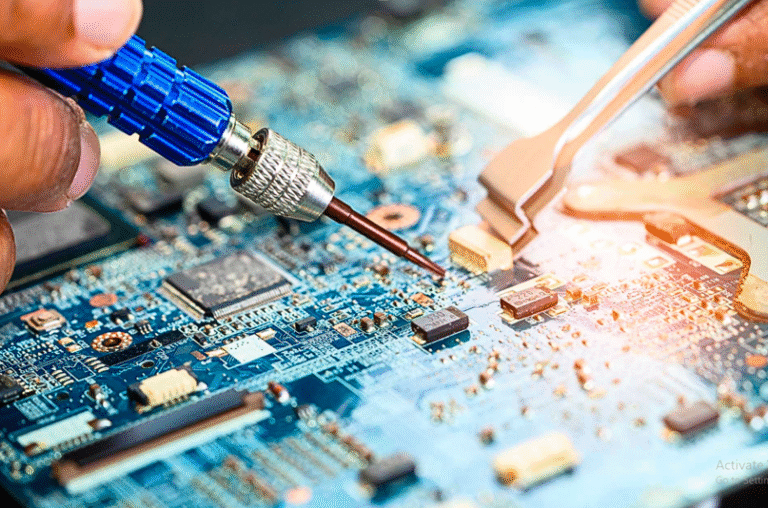

In the realm of electronics manufacturing, acronyms often cause confusion, especially for newcomers. SMT and SMD are two commonly seen terms that often appear in discussions about electronics manufacturing. Although they are closely related and sometimes used interchangeably, they refer to different aspects of surface mount technology. Understanding the distinction between SMT and SMD is essential for anyone involved in PCB assembly or electronics production.

This article clarifies these terms, explores their relationship, and provides a broader perspective on their roles within modern electronics manufacturing. The discussion also touches on relevant components like SMT peripheral equipment that support the production process.

Clarifying terminology

SMT stands for Surface Mount Technology. This technique involves placing electronic components straight onto the surface layer of a printed circuit board (PCB). SMT is a comprehensive process that encompasses the design, manufacturing, and assembly stages where surface mount components are positioned and soldered onto PCBs.

On the other hand, SMD means Surface Mount Device. This term refers specifically to the actual electronic components that are designed to be mounted using SMT processes. Examples of SMDs include resistors, capacitors, integrated circuits, and diodes that come in compact packages without traditional leads.

To put it succinctly:

- SMT: The assembly process and technology

- SMD: The physical components used in the process

The two terms are interconnected but distinctly different in focus.

See also: How Technology Is Transforming the Music Industry

The relationship between the two concepts

While SMT defines the method and overall manufacturing approach, SMDs are the building blocks placed by this technology. Surface mount devices are designed with specific mechanical and electrical characteristics optimized for automated placement. They typically have smaller footprints compared to through-hole components, enabling higher component density on PCBs.

This shift to SMDs has revolutionized electronics by allowing more compact and complex circuits with improved electrical performance. The precision required in placing SMDs demands advanced equipment such as pick-and-place machines, reflow ovens, and SMT peripheral equipment that enable efficient and accurate assembly.

Key distinctions summarized

- SMT is a process and technology

- SMD is a type of component

- SMDs require SMT for mounting onto PCBs

- SMT includes equipment and procedures beyond component placement

Understanding this distinction is fundamental for communication between design engineers, production managers, and procurement specialists.

Supporting technologies and equipment overview

The SMT assembly line relies on various machines and tools to execute the process effectively. Besides the main machines like solder paste printers and pick-and-place systems, SMT peripheral equipment plays a crucial role in ensuring smooth material handling and workflow integration.

These peripheral devices include conveyors, loaders, and inspection stations, which support continuous production and quality assurance. Their presence minimizes downtime, reduces manual intervention, and helps maintain consistent throughput and yield.

Challenges related to SMT and SMD integration

Adopting surface mount technology and handling surface mount devices introduce unique challenges:

- Component handling: SMDs are small and fragile, requiring precise automated placement to avoid damage.

- Thermal profiles: Reflow soldering demands tightly controlled temperature curves to ensure solid solder joints without harming components.

- Inspection requirements: Due to the tiny size and density of SMDs, automated inspection tools such as AOI and X-ray systems are necessary to detect placement and soldering defects.

These challenges necessitate investment not only in core machines but also in supporting peripheral systems to ensure reliability.

Advantages driving widespread adoption

The switch to surface mount devices mounted by SMT processes has become the norm because of several clear benefits:

- Space-saving: SMDs enable denser PCB layouts, facilitating miniaturization.

- Higher performance: Reduced lead inductance and parasitic effects improve electrical characteristics.

- Adaptability: SMT production systems are capable of accommodating diverse component dimensions and configurations with high efficiency.

These advantages explain why SMT and SMD have become standard in modern electronics manufacturing.

Practical considerations when choosing equipment

Choosing equipment for an SMT line requires matching the production goals with the right technology. Key points to consider include:

- Speed and accuracy of pick-and-place machines

- Compatibility with a wide range of SMD sizes

- Quality of solder paste printing

- Availability and integration of SMT peripheral equipment for efficient material flow

- Inspection capabilities for defect detection

Balancing cost with functionality ensures a production line that meets quality standards without excessive expenditure.

Final thoughts

Although SMT and SMD are interconnected, they reflect distinct aspects within the field of electronics assembly. SMT defines the manufacturing process itself, whereas SMD describes the specific components assembled using that process.

Appreciating the differences helps professionals make informed decisions about design, manufacturing, and procurement. Moreover, investing in not only the main assembly machines but also SMT peripheral equipment and inspection systems is critical to achieving efficient, high-quality manufacturing outcomes.

Mastering the terminology and understanding the operational nuances between SMT and SMD lays the foundation for effective communication and optimized production in electronics manufacturing environments.