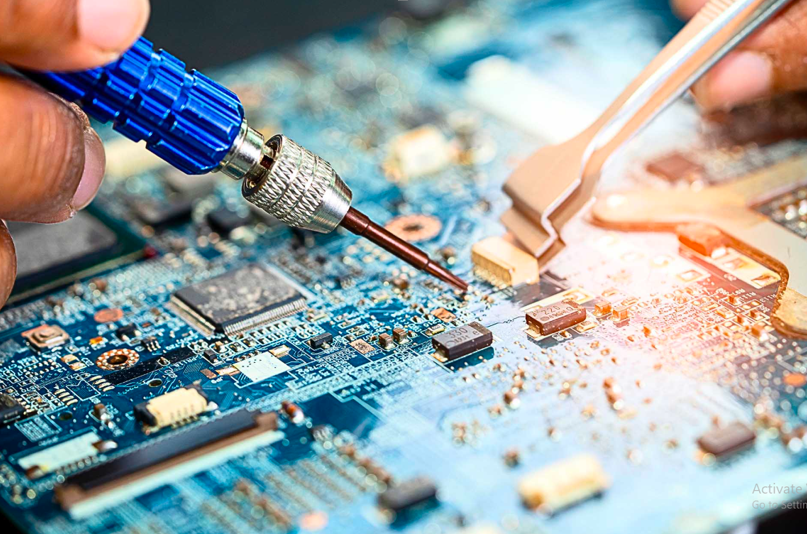

How to Choose a Reliable PCB Assembly Partner

Choosing the right printed circuit board assembly (PCBA) partner can make or break your electronics project. Whether you’re making prototypes or mass-producing devices, a trustworthy service ensures quality, on-time delivery, and cost efficiency. This article gives you tips about selecting the best PCBA provider, highlights what to look for, and shows how companies like Global Well PCBA help you succeed.

What Makes a Strong PCBA Provider

Before deciding, assess these crucial factors:

Certifications and Standards

Quality certifications like ISO 9001, RoHS, IPC-A-610, UL, etc., are essential. They show that a provider follows recognized processes and uses materials that meet safety, environmental, and reliability expectations. Global Well PCBA holds several of these, demonstrating its commitment to compliance and quality.

Range of Services Offered

A full-service provider should handle more than just soldering. Good PCBA partners offer: fabrication of boards, component sourcing, surface-mount technology (SMT), through-hole or mixed technology, inspection (AOI, X-ray), functional testing, and post-assembly services (e.g. conformal coating). This versatility simplifies communication and reduces risk of miscoordination.

Accuracy & Technology Capability

With electronics getting smaller and more complex, fine-pitch SMT, miniaturized components, rigid-flex boards, and high-frequency PCBs are increasingly common. A reliable provider should have up-to-date pick-and-place machines, sophisticated reflow ovens, precise inspection tools, and strong engineering support to handle intricate designs.

Lead Time & Turnaround Efficiency

Fast prototyping can speed up product development. Meanwhile, for large-scale runs, consistency is key. Good PCBA manufacturers balance quick prototyping with reliable production timelines, ensuring delivery is on schedule without compromising quality.

Component Sourcing & Supply Chain Management

The quality and authenticity of parts are important. A partner who sources from authorized distributors (or offers verified components), has strong vendor networks, and maintains good supply chain visibility helps avoid delays, counterfeit parts, or mismatches in specifications.

Cost vs Value

Cost is always a factor, but lowest price alone isn’t the goal. Consider the value — reliability, lower rates of rework, fewer defects, good support. Sometimes paying more upfront for better quality saves money in the long run.

Communication & Support

You want a partner who listens, reviews design files with you, offers feedback (DFM / DFA reviews), communicates during production, and delivers tests or inspection results. Transparency builds trust.

Tips about Working with Global Well PCBA

When you partner with Global Well PCBA, here are a few advantages you get that align with those strong provider traits above:

One‑stop solution: From PCB design and PCB manufacturing, through SMT/DIP assembly, to testing and conformal coating. This simplifies workflow and reduces overhead. The Global Well PCBA team supports the full spectrum, so you don’t need multiple vendors.

Quality certifications: They are certified by standards like ISO9001, RoHS, UL, etc., ensuring compliance and consistency. Ecer+1

Experience & capacity: Years in business plus large scale operations, plus OEM/ODM support. They can handle both small prototype batches and larger production volumes. Made-in-China+1

Global reach and reliability: Their infrastructure, manufacturing facilities, and client base support customers worldwide, meaning logistics, shipping, and support are more mature. Ecer

If you’re considering a specific design or product, you can visit the site for more details and request a quote using their branded service at Global Well PCBA.

See also: How Modern Crane Tech Is Changing the Construction Game

Mistakes to Avoid When Choosing PCBA Services

Even with good providers around, clients sometimes make avoidable mistakes. Here are pitfalls and how to sidestep them:

| Mistake | Why It’s Problematic | How to Avoid |

| Using vague or incomplete specifications | Leads to misinterpretation, delays, wrong parts | Always supply complete design files (Gerber, BOM, placement info), clear tolerances, desired finishings |

| Choosing the cheapest option without checking quality | May lead to defects, rework, or failure in critical applications | Ask for samples, check inspection reports, verify past case studies |

| Ignoring inspection/testing stages | Surface looks good but internal issues or reliability problems emerge later | Insist on AOI, X‑ray, functional testing, lifetime or stress testing if applicable |

| Poor communication or unclear responsibilities | Misunderstandings about who handles procurement, design changes, testing can cause delays | Clarify scope, responsibilities, deadlines up front; ensure good support from provider |

| Not considering scalability | What works for a prototype might not scale well for mass production | Check provider’s capacity, capabilities, past production volume; ensure supply chain can support your growth |

How to Get the Most from a PCBA Partnership

To get good results, follow these practices:

Start with a clear design review — get feedback from the PCBA provider early to optimize for manufacturability (DFM / DFA).

Order a prototype or small batch first — it lets you test functionality, thermal behavior, assembly tolerances, etc.

Define and agree on testing methods and quality benchmarks. (What counts as acceptable defect level? How will functional tests be done?)

Plan for supply chain challenges — lead times for certain components may vary; having alternatives helps.

Maintain open communication — share changes, updates, or problems as soon as they arise.

Conclusion

Finding a reliable PCBA partner isn’t just about cost — it’s about precision, consistency, and support. By focusing on credentials, technology capability, supply chain, and communication, you can avoid many common issues.

If reliability and comprehensive services are top priorities for you, globalwellpcba.com is a provider worth considering, thanks to its strong certifications, wide service offerings, and expertise across PCB technologies.